CONTINUOUS LENGTH FOR

5,5 - 8/10 - 12 - 18/19 m SEGMENTS

FRP / GRP

laminate range for passenger transport

GRP / FRP laminates of Decopan Bus fulfil high safety standards as electrical safety as well as special requirements as fire safety on railway vehicles with a proven performance for years in any weather, on any road in Turkey and abroad.

Specs as continuous length and improved paint performance or self-coloured options provide manufacturers with great flexibility.

Solid collaboration with top brands...

Top domestic and international brands of Turkey as; Otokar, Temsa, Man, Bozankaya, Karsan, manufacturing buses and coaches carrying millions of passengers in transport fleets across Europe, use Decopan Bus FRP / GRP laminates a.k.a. FRP / GRP sheets.

Vehicles with Decopan Bus FRP / GRP laminates run all directions through numerous countries thanks to sustainable close collaboration of Fibrosan with the manufacturers in quality and quantity. The exemplary collaboration with Otokar which awarded Fibrosan, and exporting to 50+ countries, is a case in point.

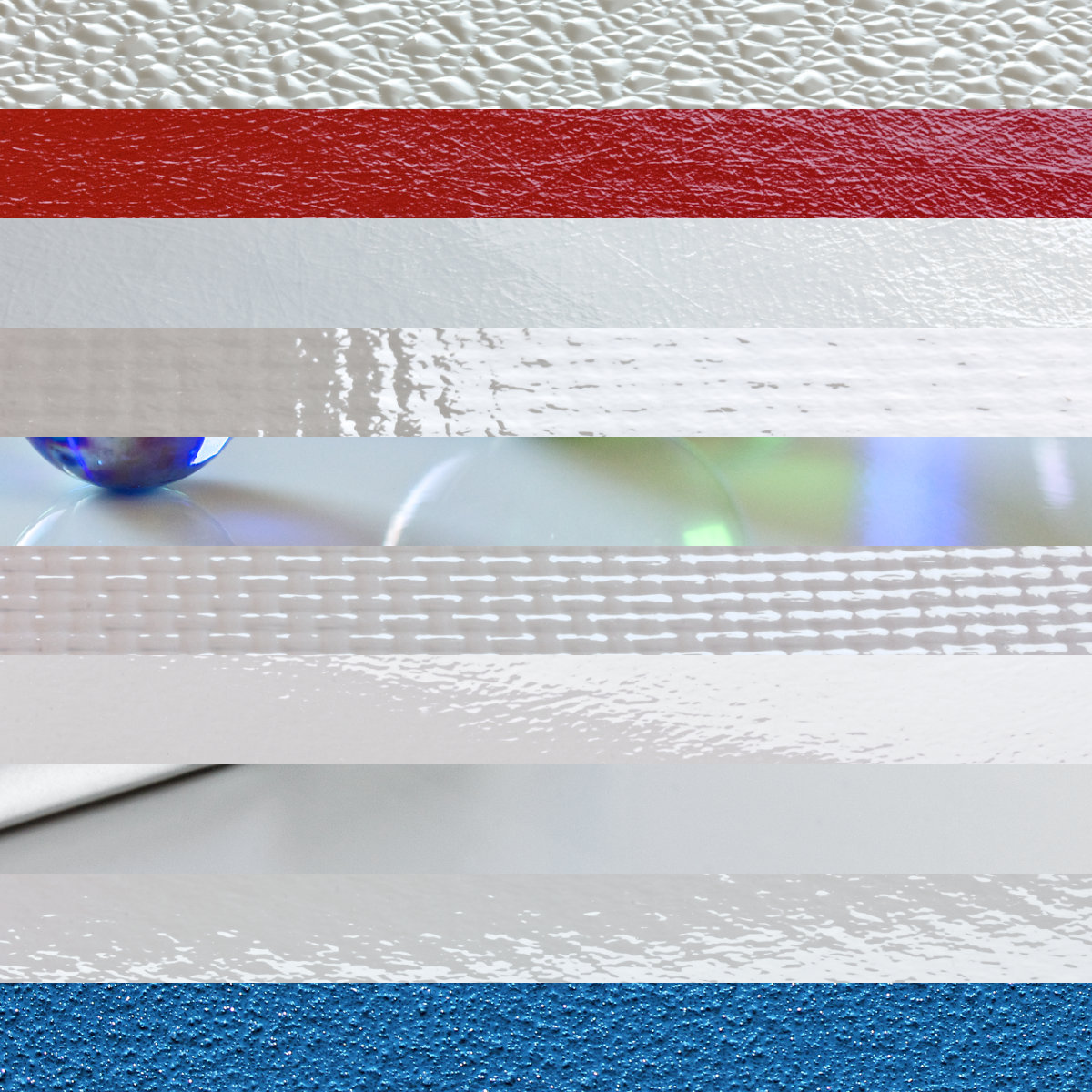

108 options and more to come...

Decopan Bus range of FRP / GRP laminates a.k.a sheets, include high performance products essential for manufacturing passenger transport vehicles as minibuses, midibuses, buses and coaches.

Easy-to-sterilize Antibacterial FRP / GRP laminates are observably convenient and advantageous for public transport where vital importance of hygiene became evident after global pandemic.

Our Anti-Slip, tested laminates are used for cabin flooringsHigh-performance Decopan Bus Anti-Slip laminates (sheets), classified M1/F1 according to NF F 16-101 are used safely in passenger transport vehicles.

Strength and safety

Decopan Bus FRP / GRP sheet samples are tested at trusted internationally accredited laboratories.

Public transport vehicles manufactured with our glass fibre composite laminates carry millions of passengers in several countries everyday.

- Resistance

Heat resistant from - 40 °C to + 120 °C.

Moisture resistant. Waterproof.

Resistant to UV and surface aging.

Resistant to chemicals.

Anti-corrosive.

Resistant to impacts and crashes.

- Public Transport Hygiene

Decopan Bus FRP / GRP laminates (sheets) are easily disinfectable with all popular disinfectants.

Prevention of bacterial growth after disinfection and ease-of-cleaning / disinfection are tested and reported by Biolab.

Antimicrobial activity testing of Antibacterial Decopan Bus FRP / GRP sheet samples conducted in accordance with JIS Z 2801 (ISO 22196).

- Fire Safety

Some test results of Decopan products with our optional Fire Safety special formula alternatives are as follows:

Anti-Slip laminate samples have been tested in accordance with NF F 16-101 standard and classified as M1/F1.

Tested in accordance with BS 476 Part 7 standard and classified as Class 1.

Tested according to DIN 4102 and classified as Class B2 Fire Resistant.

- Electrical Safety

Decopan Bus FRP / GRP laminates (a.k.a. sheets) are electrically non-conductive and avoid high voltage arc discharges.

- Food Safety while Travelling

Laminates (sheets) comply with Turkish Food Codex Regulations with Certificate of Compliance to Turkish Food Codex Regulations.

Conformity of Decopan sheet samples to HACCP and ATP-C criteria are certificated by TÜV Süd Gruppe ATP Control Place Munich report

Comply with global food regulations in accord with the test report of Leatherhead Food International.

- Additional Safety in Hygiene Areas

Laminates prevent bacterial, fungal and mold growth in toilet cabins, sleeping cabins and food preparation areas.

Technical specs for Anti-Bacterial and Extra Strong GRP / FRP laminates vary based on product selected.

Fire Safety is optional.

All product, product specifications and data are subject to change without notice to improve reliability, performance, function, design or otherwise. Contact our Sales Team for latest specs and other data.

FRP / GRP laminates are tested at trusted internationally accredited laboratories.

Decopan Bus

laminates have limitless variants under 9 main categories.

Extra reinforced for extra resistance

Specially improved for paint process

↔↕ Suitable for monolithic bus roofs

Customization of thickness and width upon request

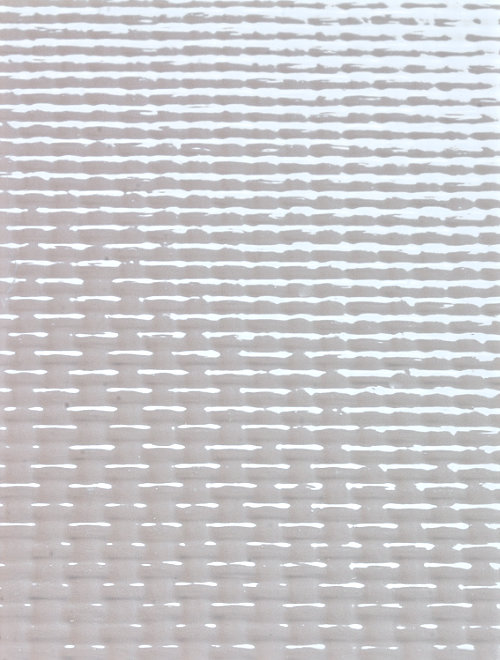

Chopped Strand Mat, Woven Roving and tissue

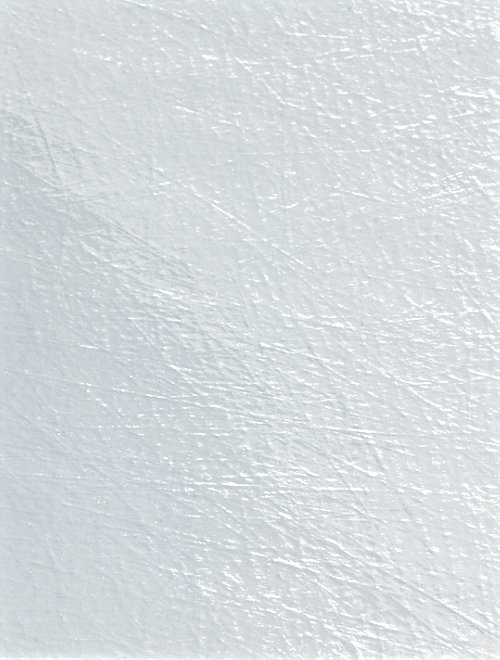

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.40 - 3.00 mm

⇄ 60 m

Uniform thickness

Film grooved, smooth, open fibers bonding side options

↔ max 3200 mm

↕ 1.30 - 5.00 mm

High tensile and mechanical strength

Glossy or matt finish

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.40 - 3.00 mm

⇄ 60 m

Uniform thickness

Film grooved, smooth, open fibers bonding side options

↔ max 3200 mm

↕ 0.80 - 1.60 mm

High resistance

High elasticity

Glossy or matt finish

Extra UV resistance and weathering protection

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.00 - 5.00 mm

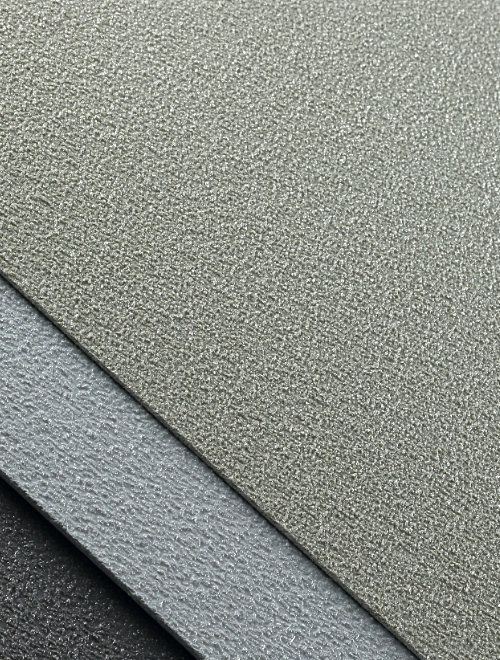

Budget solution for interiors and underfloor use

Self-coloured structure

Low Thermal Expansion Coefficient

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.15 - 5.00 mm

Low Thermal Expansion Coefficient

Glossy or matt finish

High UV resistance

Smooth, sanded (rough) or corona-treated bonding side

↔ max 2950 mm

↕ 1.20 - 5.00 mm

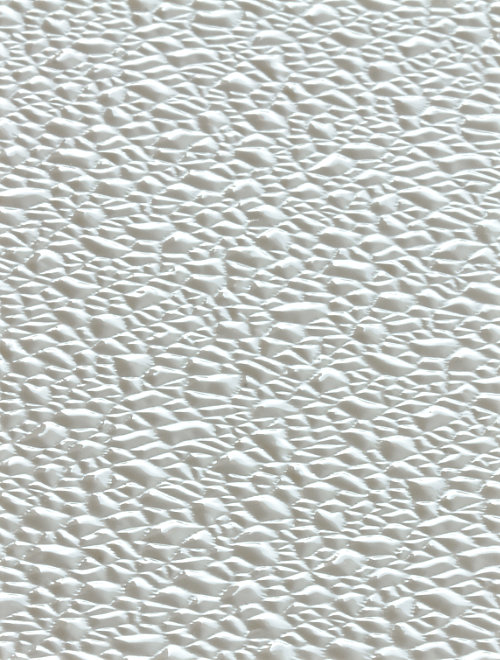

Best for easy-to-clean interiors

Smooth, sanded (rough) or corona-treated bonding side

Fire resistance with M1/F1 rating

↔ max 2800 mm

↕ 2.00 - 2.30 mm

Dimensions suitable for monolithic flooring

Ready-to-use laminates

Smooth, sanded (rough) or corona-treated bonding side